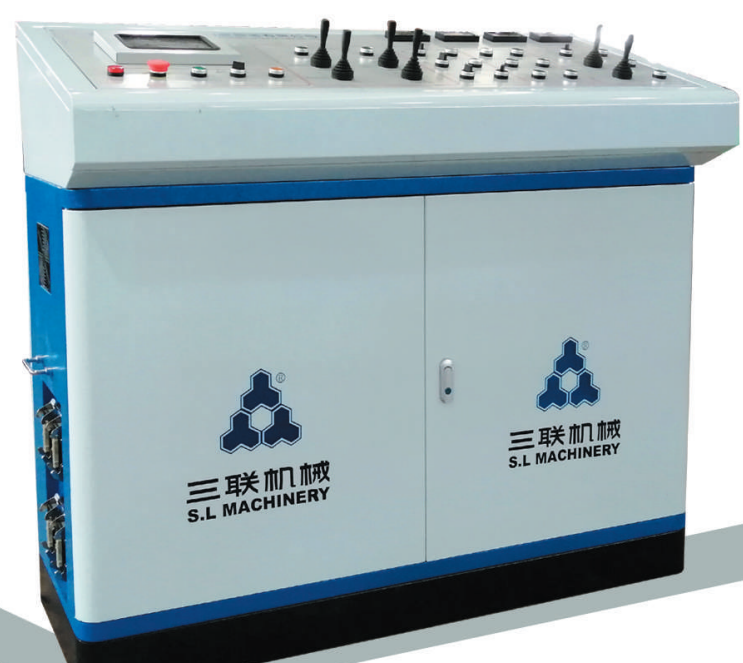

SLST1200 Servo Motor Intelligent Concrete Block Making Machine

Automatic Servo Concrete Cement Block Brick Making Machine

Item no.: SLST1200 Automatic S

Product origin: China

The servo vibration system contains a servo controller,four servo drivers and four servo motors(the quantity of servo drivers and servo motors can be changed according to requirements);The vibration table is composed of a vibration box and a vibration platform.

Turn on the servo vibration system and the vibration table distributes material at a low frequency before pressing. After the material distribution finishes,vibration presses material at a higher frequency.

Product Description:

With servo technology, it can produce building blocks, municipal road tiles, PC floor tiles, high-end stone like floor tiles, blocks of water conservancy slope protection and other products in layers.

With high molding speed, stable and reliable operation, it makes products with high density and good stability.

|

MAIN PARATMETERS |

|

CAPACITY TABLE |

||||

|

ITEM |

MEASUREMENT |

|

BLOCK |

SAMPLE |

SLST1200 |

|

|

PALLET SIZE(MM) |

1400*950 |

|

HOLLOW BLOCK (390X190X190MM) |

|

PCS/PALLET |

12 |

|

MAX. PRODUCTIVE AREA(MM) |

1300*900 |

|

SOLID BLOCK (240X115X53MM) |

|

PCS/PALLET |

73 |

|

MIN. PRODUCT HEIGHT(MM) |

45 |

|

PAVER (200X100X60MM) |

|

PCS/PALLET |

48 |

|

MAX. PRODUCT HEIGHT(MM) |

500 |

|

I SHAPE BLOCK (198X165X60MM) |

|

PCS/PALLET |

30 |

|

CYCLE TIME(S) |

12~25 S |

|

ZIGZAG BLOCK (225X112.5X60MM) |

|

PCS/PALLET |

35 |

|

SHORTEST CYCLE TIME(S) |

SOLID BLOCK 12 |

|

SQUARE BLOCK (250X250X60MM) |

|

PCS/PALLET |

15 |

|

PAVER 20 |

|

GRASS BLOCK (400X200X60MM) |

|

PCS/PALLET |

12 |

|

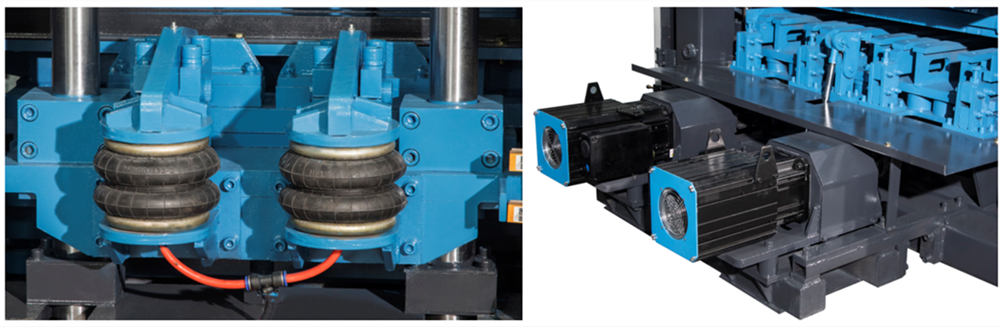

Airbag: The airbag structure is adopted, which is convenient for the installation and replacement of mold, and the amplitude of the mold frame can be adjusted by air pressure during production, which is suitable for large-scale equipment.

Servo Vibration System:

Adjust the phase angle to start or eliminate vibration.It realizes higher efficiency,lower energy consumption,better vibration effect and easy maintenance.

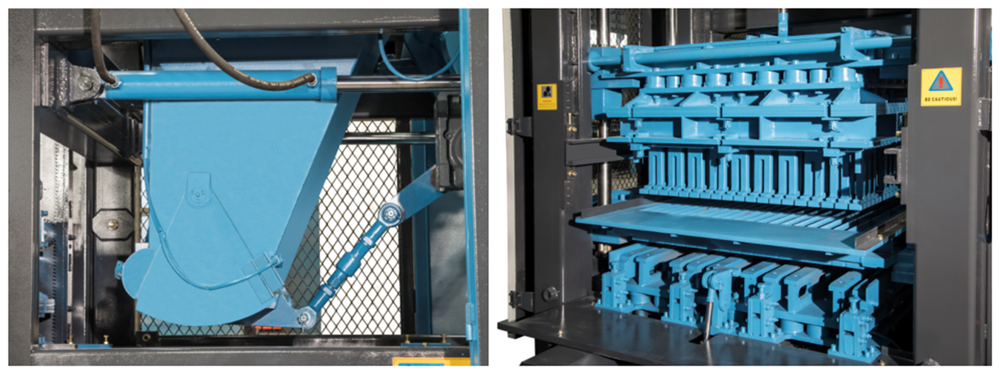

Base material bin and discharge parts: hydraulic cylinder control, storage of mixed raw materials.

Servo Hydraulic System

Advantages of hydraulic system:

Energy consumption saved more than 30%,noise is 10-20 DB lower and the working efficiency is 10-20% higher than the traditional hydraulic system.

The heat produced by servo hydraulic system is just 10%-30% of the traditional hydraulic system.

PLC Controller System

It realizes automatic control of production line and independent control of each system; System program is provided with linkage,interlock status display.It also realizes status display,failure diagnosis and data input through the computer implementation.

Batching Machine:

With the measurement permission standard,fast and low batching measurement can be realized. With vibration device,it ensures smooth blanking.

According to different aggregates and different requirement about products,and the mix ratio of aggregates, it adopts the automatic weighing of high precision three-point induction sensor.

|

机型/TYPE |

称量斗容积/Volume of Weigh hopper |

出料斗容积Volume of Unloading Hopper(M3) |

生产率 Productivity (M3/h) |

最大称量值 Max Weigh Value |

可配骨料种数 Batching Category of Aggregate |

上料高度Height of loading material(mm) |

配料及卸料方式Batching&Unloading Method |

功率 Power(KW) |

外形尺寸 Frame Measurement(MM) |

质量 Net Weight(T) |

|

PL800 |

2M3 x 2 |

0.8 |

48 |

1.5T |

2 |

2300 |

水平或T字形电动皮带机Horizontal or T shape belt conveyor |

6.6 |

5470x1820x2700 |

2 |

|

PL1600-3 |

7M3 x 3 |

1.6 |

96 |

3T |

3 |

2900 |

13 |

11650x2300x3450 |

5 |

|

|

Pl1600-4 |

7M3 x 4 |

1.6 |

96 |

4T |

4 |

2900 |

16 |

15200x2300x3450 |

7 |

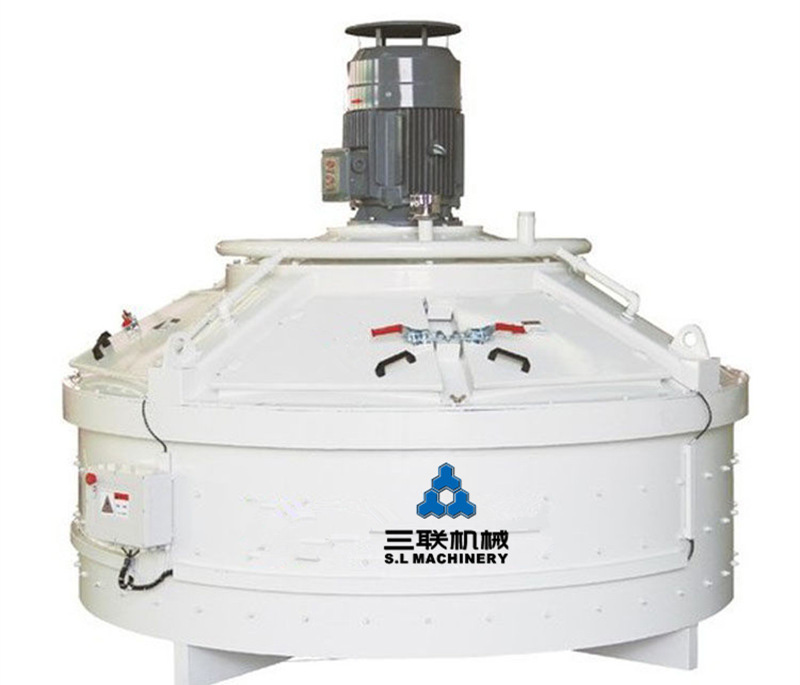

Mixing System :

Vertical Shaft Planetary Mixer:

The mixing track is complex, mixing is strong and even, efficiency is high, maintenance and cleaning is easier.

Select electrical accessories of international famous brand, such as Siemens,SEW,Toledo etc.,performance is more stable.

Application :