HIGHLIGHTS

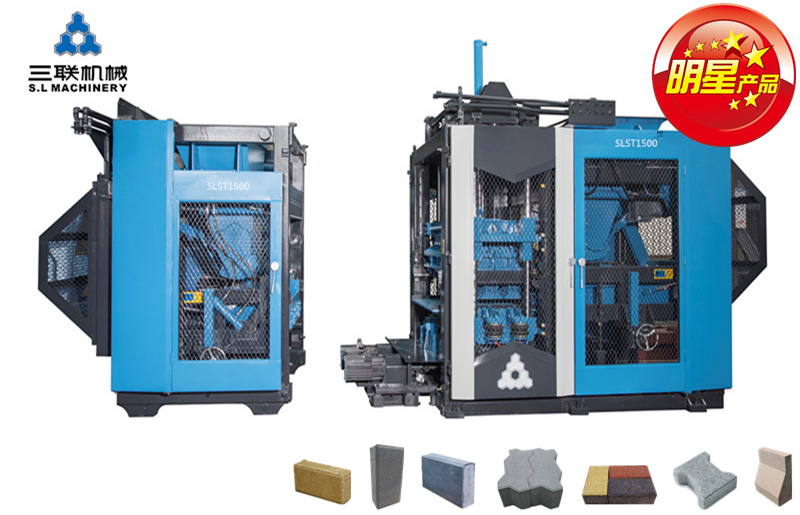

ONE、Introduction on Automatic Servo System Block Making Machine

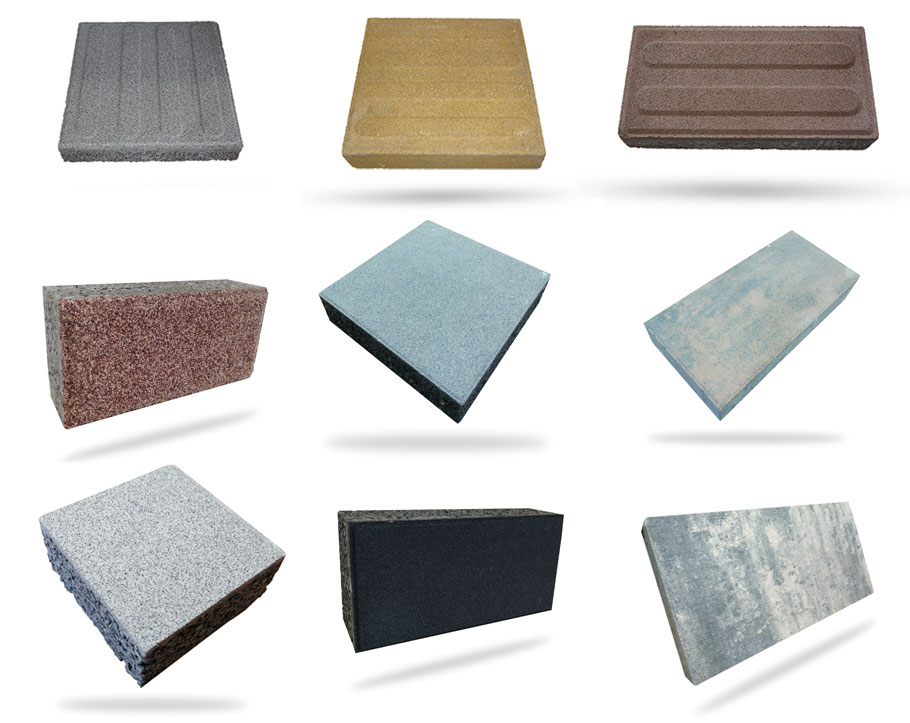

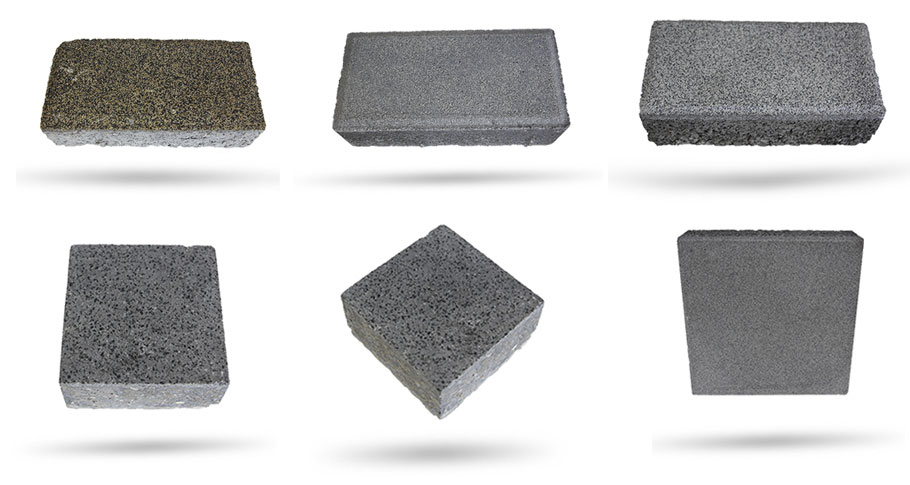

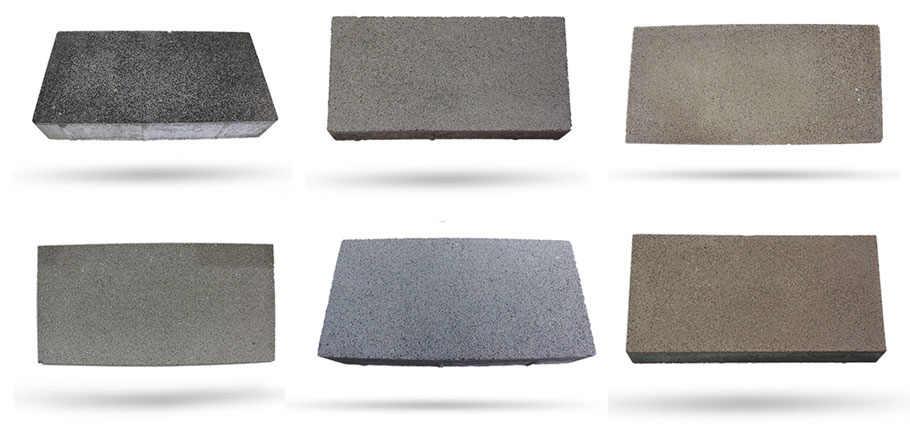

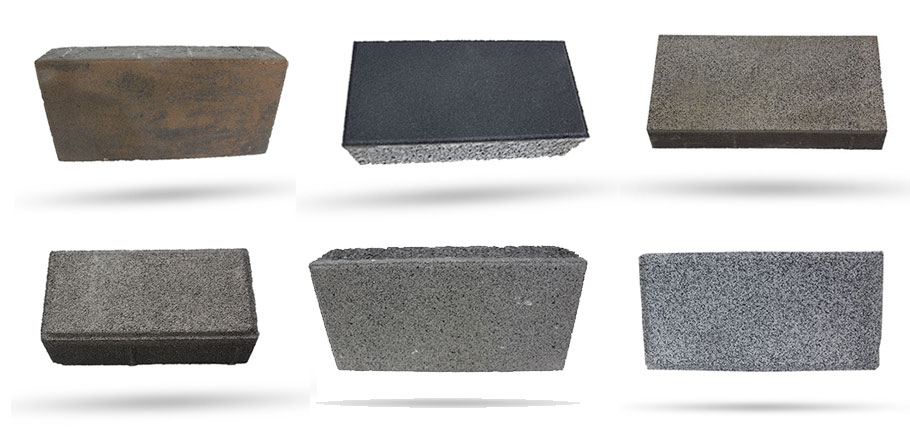

The automatic servo system block machine not only shortens the brick forming cycle, greatly increases the output of concrete products, but also effectively improves the quality of concrete products. It is suitable to produce various high-strength, high-quality concrete blocks, permeable bricks, and water conservancy slope protection bricks , Curbs,paving stone and other concrete products.

The automatic servo system block machine reduces the energy consumption, also it reduces noise pollution by more than 10%, increases working efficiency by 30-40%, and the good yield of bricks made by servo brick machine can be increased by more than 10%.

TWO、Servo System Block Machine Advantages

Synchronous servo motor advantage

●High precision synchronization

●Small current Big torque

●High shockproof level

●shafts high speed response,Control precision

Electro-hydraulic Servo Advantage

●Energy saving rate improves

●Extended hydraulic system service life

●Low noise,dynamic fast response

●Reduce hydraulic elements

●Improve holding pressure precision

●Improve finished product quality

The automaticservo system block machinehas obvious advantages over the traditional blockmakingmachine in terms of performance, product quality, energy saving and consumption reduction.

As a basicenvironmentally friendlypolicy of engineering construction, building energy efficiencywill beenforcedinternationwide. Countries around the world will also successively formulate and promulgate a series of standards and regulations to promote the smooth development of building energy conservation. The automaticservo system block machineis a new type of wall material equipment, in line with theinternational industrial policy guidelines.

Asthe necessary and urgentrequirements for green, environmental protection,the continuously increased request onenergy saving and consumption reduction,andthe integration of industry and information technology,the future development of brick machine is bound to be in this direction, and constantly improve, the new generation of technology will replace the old technology.

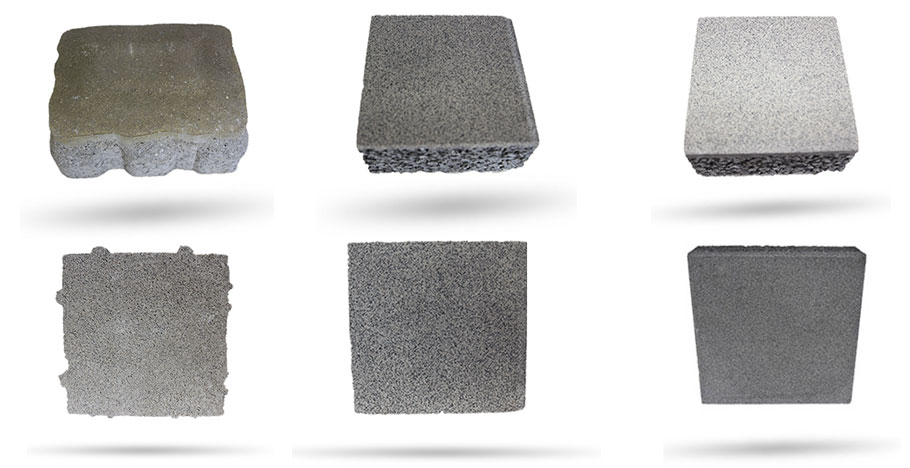

THREE、Concrete paving stone products