Practicing green development

With the acceleration of urbanization, activities such as real estate development and industrial construction have generated massive amounts of construction waste. How to achieve "turning waste into treasure" through resource recycling has become a critical topic in promoting green development. S.L Machinery actively embodies green development principles by utilizing servo-powered eco-friendly brick-making equipment to transform industrial solid waste such as coal gangue, construction waste, and fly ash into high-density cement products, truly realizing the concept of "turning waste into treasure."

Technological Innovation as the Core Driver

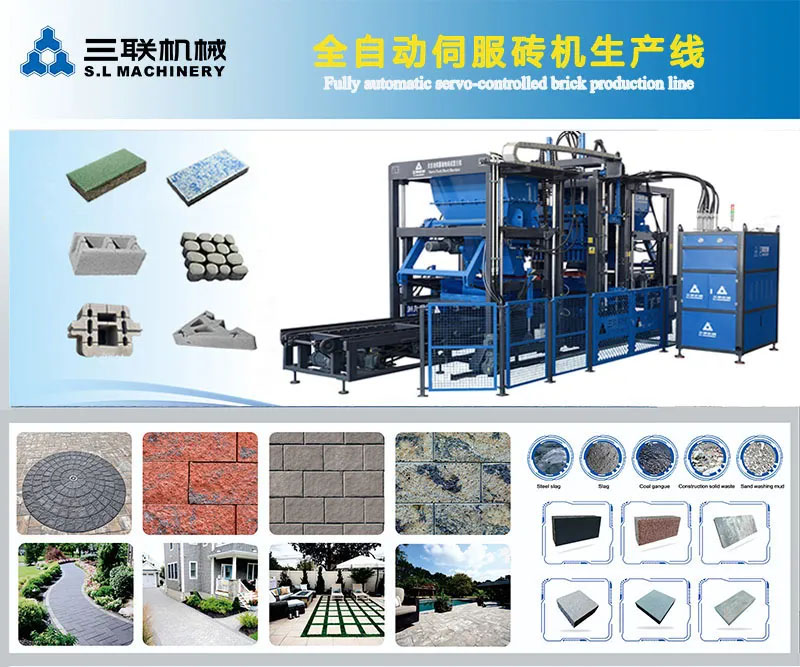

Technological innovation serves as the core driving force in achieving green transformation. S.L Machinery exemplifies the value of technological innovation through its SLST series of fully automatic servo wall and floor block equipment.

Energy Efficiency: By integrating advanced servo technology, this brick production line can significantly reduce energy consumption by over 30%, making it an eco-friendly choice for manufacturers.

Automation: The automation capabilities of the production line reduce manual labor and streamline the production process, thereby enhancing productivity and cutting costs.

Quality Assurance: Precise control over the production process ensures product consistency, meeting the high standards of the building materials market.

Versatility: This brick-making production line is multifunctional, capable of producing various wall and floor blocks to meet diverse construction needs.

Comprehensive Support: From custom design to after-sales maintenance, ensuring the smooth operation of projects.

Through the SLST series servo brick-making equipment, the company not only helps customers achieve cost reduction and efficiency improvement but also provides them with a replicable and scalable industrial pathway from "construction waste to green building materials."