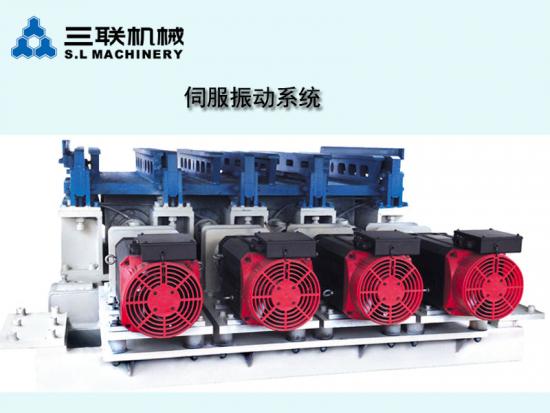

Servo Vibration System

The servo vibration system consists of a servo controller, four servo drivers and four servo motors (the number of servo drivers and servo motors can be increased or decreased according to needs); The vibration table is composed of a vibration box and a vibration table. Before pressing.

servo vibration system

The servo vibration system consists of a servo controller, four servo drivers and four servo motors (the number of servo drivers and servo motors can be increased or decreased according to needs); The vibration table is composed of a vibration box and a vibration table. Before pressing.

the servo vibration system is turned on and the vibration table is distributed at a lower frequency. when the cloth is finished , the vibrator vibrates at a higher frequency while the brick is pressed.

![]() Adjust the phase Angle vibration, vibration elimination:

Adjust the phase Angle vibration, vibration elimination:

1 . The speed is accelerated in advance to the predetermined working speed , and the phaseAng![]() e is changed to start vibration. (No excitation

e is changed to start vibration. (No excitation

force is maintained at a phaseAngle of 180* while accelerating)

2 . compared with ordinary motor acceleration,deceleration,vibration lifting and vibration elimination , the cycle saving is more than 1.5s.

3 . Improve product quality and make it easier to shape special bricks.

![]() The amplitude and frequency can be adjusted:

The amplitude and frequency can be adjusted:

1.The rotational speed controls the frequency of vibration and the Angle controls the exciting force to achieve the amplitude and frequency of vibration , which can be adjusted at the same time.

2. It is easier to produce special bricks to improve product quality.

3.Improved product compactness.

![]() compared with the traditional frequency conversion control , the comprehensive

compared with the traditional frequency conversion control , the comprehensive

advantages include:

1 . More efficient. The vibration acceleration time can be less than 1s (molding acceleration) , and the vibration elimination time can be less

than 0.3s (molding acceleration).

2 . Lower energy consumption. Each servo motor is individually controlled , without interference between each other, which overcomes the problem of energy offset and energy loss caused by synchronization , and achieves better energy-saving effect.

3 . Better vibration effect. Adopt ful lcosed loop control , high synchronization , more stab![]() e excitation force.

e excitation force.

4 . Easy to maintain. Each servo motor is a separate unit, no mechanical synchronization between each other, more convenient maintenance.