As a leading mining nation, China faces significant challenges with tailings storage. The comprehensive utilization of tailings is crucial for both resource security and ecological protection. With technological advancements, tailings are being transformed from an "environmental burden" into "urban minerals," particularly finding new life in the construction sector. Through innovative technologies, S.L Machinery converts tailings into lightweight wall panel, delivering sustainable solutions for green building.

Tailings-Based Wall Panel: From Waste to Green Building Materials

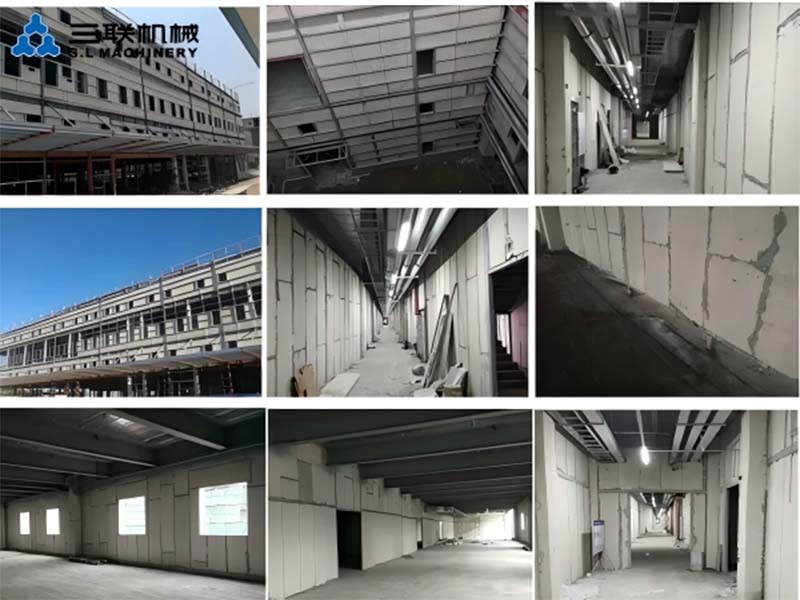

S.L Machinery wall panel production line repurposes tailings into high-performance lightweight wall panels, pioneering a green development model that turns solid waste into construction materials. Compared to traditional building materials, tailings-based panels offer distinct advantages:

Eco-Friendly Waste Reduction: Directly consumes tailings, minimizing storage pollution

Superior Performance: Lightweight yet high-strength, with fireproof and soundproof qualities—ideal for commercial/residential buildings, hospitals, schools, and more

Cost Efficiency: Replaces cement and aggregates, reducing raw material costs

Technology-Driven Green Transformation

By refining core technologies such as aggregate ratios and curing agent formulations, S.L Machinery has overcome challenges like tailings instability and low strength, ensuring panels are both eco-conscious and highly functional. Today, these lightweight wall panels are widely adopted in prefabricated construction, supporting the industry's "dual-carbon" goals.

S.L Machinery Wall Panel machine utilizes tailings as raw materials to produce prefabricated building panels, not only resolving the challenge of mining waste disposal but also establishing a circular model of "resource-product-renewable resource." This innovation provides a replicable template for green development in the industry.